wire machine

*The above parameters are for reference only, please contact our sales department for exact parameters.

Keywords:

Category:

Product Description

Main technical parameters (specifications)

Dimensions: 4.2×0.8×1.45(m)

Power supply: 380V, 50HZ

Motor power: 0.37KW stepless variable speed

Heating tube power: 1.0 KW

Wax tank heating power: 3.0 KW

Weight: 260kg

Wax wire diameter: 1.2-3.0(mm)

Average length of over-wax: 2000 m/h

|

|

|

|

|

|

|

|

|

|

|

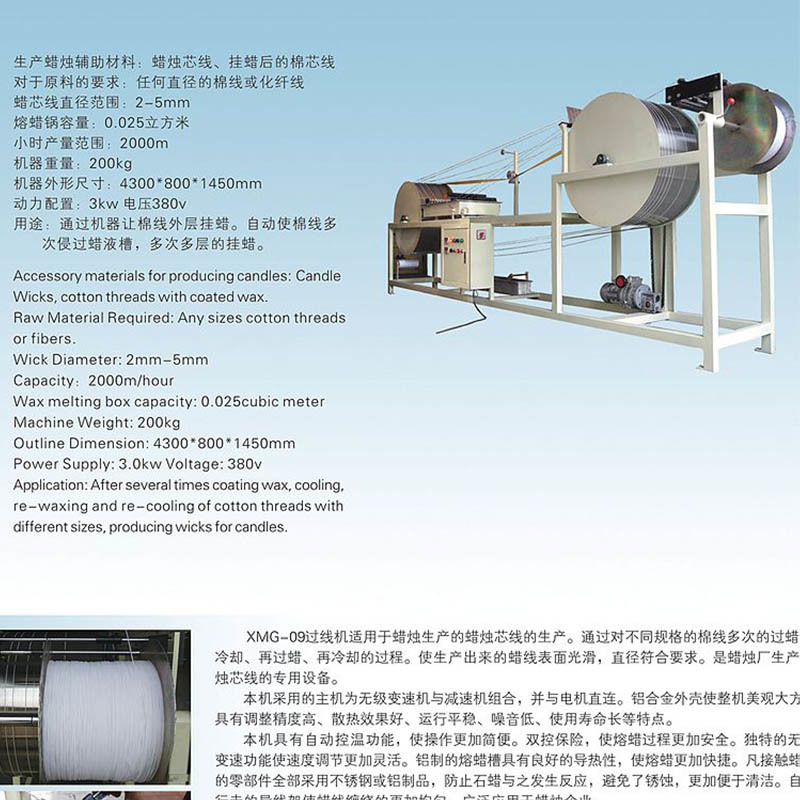

XMG-09 threading machine (candle core wire hanging wax machine)

XMG-09 threading machine is suitable for the production of candle wick lines for candle production. Through the process of waxing, cooling, waxing again, and re-cooling of cotton threads of different specifications. The surface of the wax wire produced is smooth and the diameter meets the requirements. It is a special equipment for candle factory to produce candle wick wire.

The main engine used in this machine is a combination of stepless transmission and worm reducer, and is directly connected to the motor. The aluminum box gold shell makes the whole machine beautiful and generous, with high adjustment accuracy, good heat dissipation effect, smooth operation, low noise, long service life and other characteristics.

This machine has an automatic temperature control function, making the operation more convenient. Dual control insurance makes the wax melting process safer. The unique stepless shift function makes the speed adjustment more flexible. The aluminum molten wax tank has good thermal conductivity, making the molten wax faster. All parts that come into contact with wax water are made of stainless steel or aluminum products to prevent paraffin from reacting with it, avoid rust, and make it easier to clean. The automatic walking wire holder makes the wax wire winding more evenly, and is widely used in candle enterprises.

Related Products

Get a free product quote