Automatic pressed tea wax production line

*The above parameters are for reference only, please contact our sales department for exact parameters.

Keywords:

Category:

Product Description

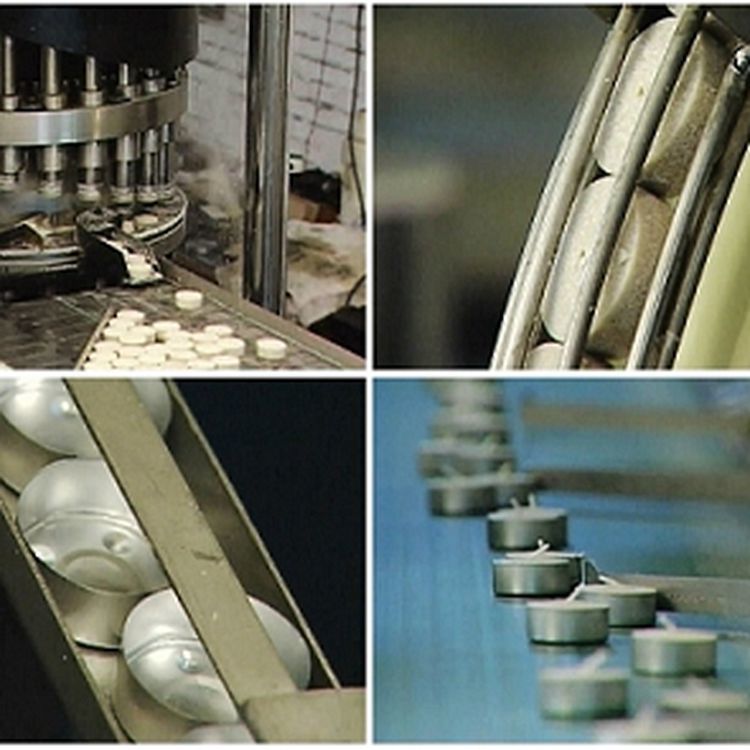

Varieties of candles produced: white wax with candle wicks and aluminum

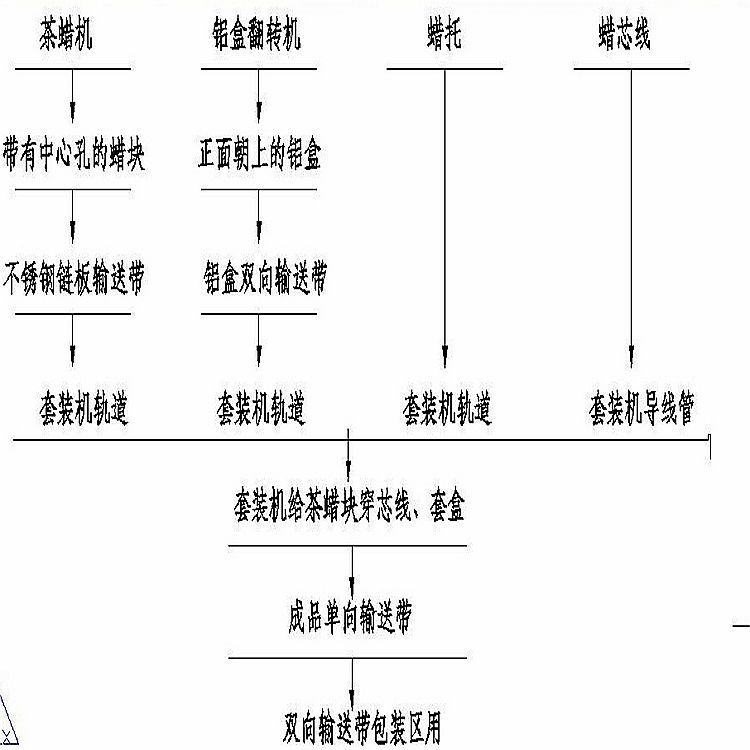

Tea wax completion process: tea wax block in the center hole - → wear wax core wire - → clamped together with the wax holder - → set aluminum bond - → finished tea wax

Candle diameter range: 37mm ( other sizes need to be customized)

Candle height range: 12-14mm (other sizes need to be customized)

Hourly output range: 35,000 speed adjustable (per six sets)

Automatic powdering device: This machine is equipped with automatic powdering device

Candle top shape: flat top umbrella shaped top convex concave top, etc

Weight of the whole line: 3000kg

Machine dimension: 8000* 2000* 2900mm

Power configuration: 9kw

Uses: For the production of tea wax pressed with wax powder as raw material (from the assembly line down the meter is both a finished candle with a candle wick line and aluminum)

|

|

|

|

Automatic pressed tea wax production line configuration:

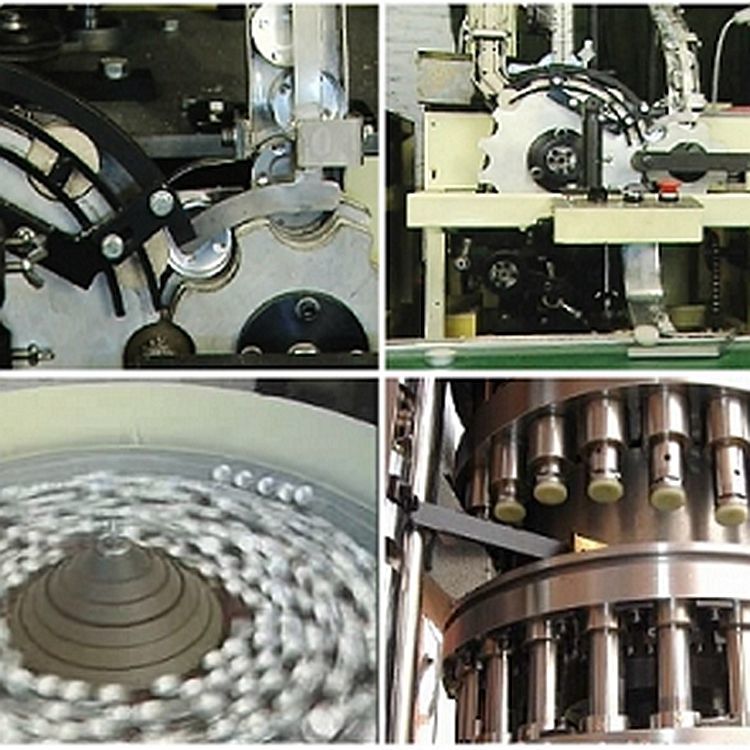

1. This production line is composed of RY18 or RY24 automatic rotary wax machine; 5-7 sets of automatic suit machines; One aluminum folding machine; One aluminum two-way conveyor; One two-way conveyor for wax blocks; A finished candle conveyor consists of one.

2. The production line design is reasonable, the manufacturing accuracy is high, and there is an advanced electronic control system, which can control all kinds of machines in the production line arbitrarily and operate it easily.

3. The production line is a combination of electronic technology and machinery to achieve fully automatic production, so it can save a lot of manpower.

Crimping products

Related Products

Get a free product quote