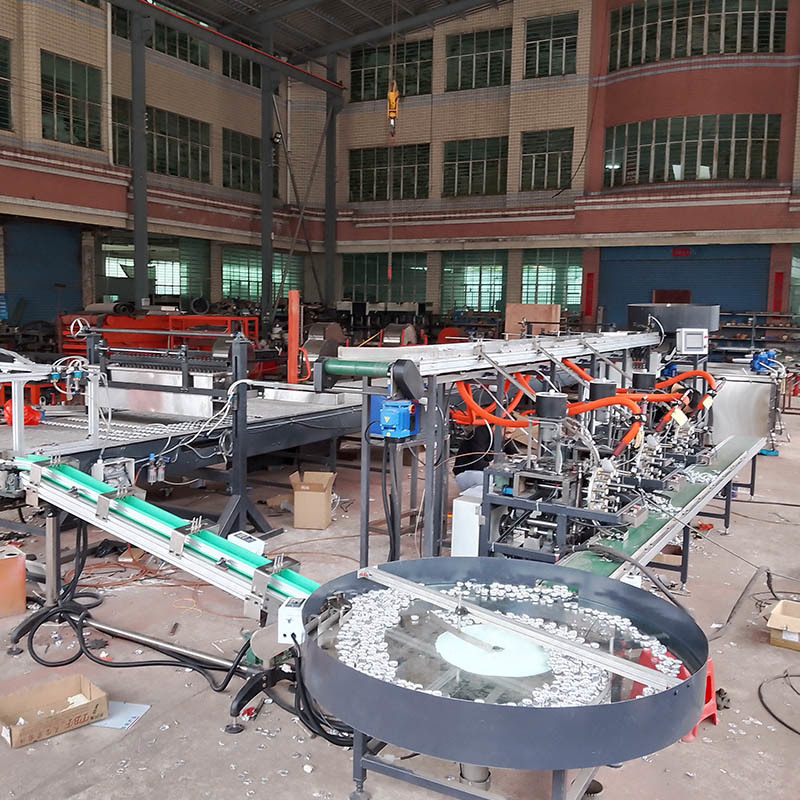

Fully automatic filling production line

*The above parameters are for reference only, please contact our sales department for exact parameters.

Keywords:

Category:

Product Description

| Automatic filling tea wax production line is a filling production line with perfect combination of high automation and full machinery developed by our company. It realizes high-speed mechanized connection from the sorting of wax boxes to the set and filling of wax boxes. The simple control of the LCD touch screen and the intermediate intervention of no one factor fully improve the production efficiency. | Model: XCG13 |

| Wax melting pot temperature range: 0-200 degrees Celsius (computer automatic control temperature) | |

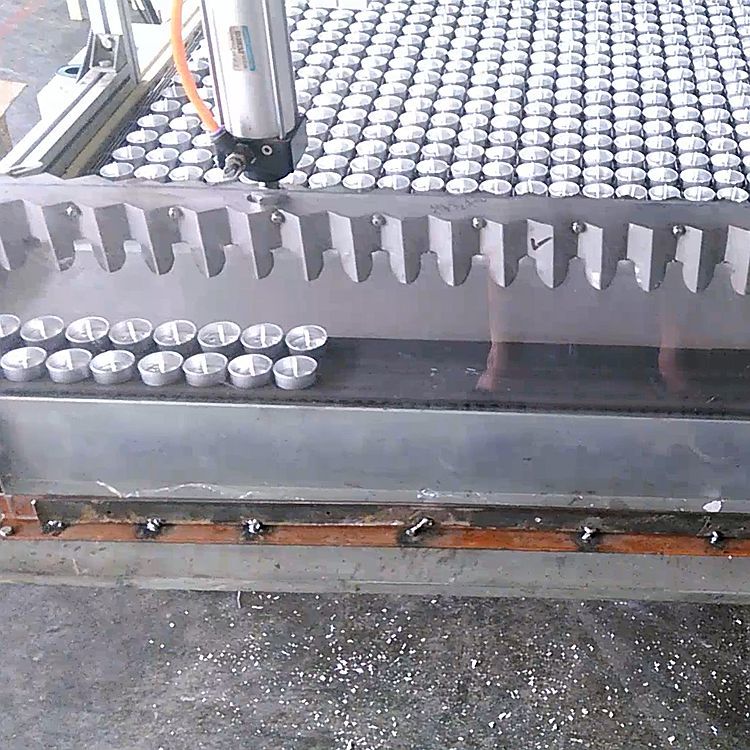

| Wax box diameter: Φ37mm (other sizes can be customized) Height: 7-26mm | |

| Wax solution in wax pot filling capacity: 300 liters | |

| Power supply voltage: 380v Equipment total power: 28kw The transmission power of the network belt is 1.5kw | |

| Output (adjustable): 18000/h | |

| Weight: 15000kg | |

| Applicable raw materials: paraffin, ghee, stearic acid, carnauba wax, soybean wax, etc | |

| Actual floor area in the workshop: 32L*6W*2H | |

| Remarks: XM-GZX tea wax filling production line consists of a wax box sorting machine, four sets of machines, a storage box push box device, a filling melting wax device and a conveyor belt. This line can be filled with paraffin, tea wax and stearin wax. The LCD monitors the whole process. Uninhabited intervention and a high degree of automation will increase productivity and productivity. |

The automatic filling tea wax production line has the following parts:

1, aluminum (flame retardant plastic box) box turning machine;

2. Four-station aluminum round-trip conveyor belt;

3. Pneumatic aluminum (flame retardant plastic box) dispenser;

4. Three or four sets of aluminum bonding (flame retardant plastic box) core sticking machine;

5. Four-station adhesive one-way conveyor belt with wax core wire aluminum;

6. Diameter 1, 5 meters container buffer turntable;

7. Container accumulation material climbing conveyor belt (double channel);

8. Automatic pneumatic push-in device (double row);

9. The first set of filling machine (including the insulated pot, the first filling double row simultaneous filling);

10. The second set of filling machine (including the insulated pot and the second filling double row);

11. Ironing and leveling device (optional);

12, stainless steel conveyor mesh belt 32m *1, 2m;

13. Intelligent electronic control system;

14. Baking belt device (optional);

15. Cooling device (optional);

16. Wax core wire leveling device (optional);

17. Round-trip with conveyor belt for packaging (optional).

|

|

|

|

Production of candle varieties: there are containers of tea wax. For example, aluminum tea wax, flame retardant plastic box candles, ghee lamps, etc.

Candle completion process: automatic box filling→ adhesive wax core wire → conveyor belt→ the first filling→ the second filling → the finished candle after cooling

Molten wax pot temperature range: 0- 200 degrees Celsius (computer controlled temperature)

Wax liquid filling capacity of molten wax pot: 300 liters

Candle container diameter range: 37mm ( other sizes need to be customized)

Candle container height range: 7-27mm ( other sizes need to be customized)

Hourly output range: 18,000 speed adjustable (according to the amount of tea wax)

Applicable raw materials: paraffin wax, ghee wax, stearic acid, carnauba wax, etc

Average weight error of finished product: ≤0.2g

Weight of the whole line: 15000kg

Machine dimensions: length, width and height 32m* 6m * 2m

Power configuration: total power 28kw

Transmission power of the network belt: 1.5kw voltage 380v

|

|

|

|

|

|

|

|

|

|

|

Related Products

Get a free product quote