Semi-automatic candle filling production line

*The above parameters are for reference only, please contact our sales department for exact parameters.

Keywords:

Category:

Product Description

Semi-automatic candle filling production line:

1. This production line is an ideal equipment for filling various container candles and various special-shaped candles;

2. The machine is made of carbon steel and stainless steel, especially the wax part of the machine is made of stainless steel;

3. There are two production lines: automatic and semi-automatic. The wax-making process is controlled by electronic technology, which is safe and reliable.

| project | The main technical parameters | Outline of Machine Composition | ||

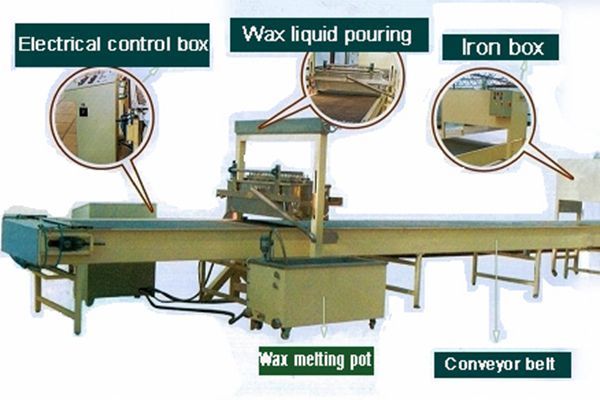

| device name | XM-GZX1200 Filling Candle Production Line | This product is a special equipment for filling candles. It consists of a container pushing device, a wax liquid filling machine head, a filling box, a conveyor belt, a wax melting box and an ironing box. It is suitable for filling various containers with diameter below 110mm and height below 250mm. The machine has two control modes, automatic and manual. The operation is flexible and simple, and the intuitive digital display device is more convenient to adjust the filling temperature and time. Widely used in candle companies. It can also be improved and customized according to customer requirements. The running speed of the conveyor mesh belt is controlled by a frequency converter, and the speed can be adjusted according to the cooling time of the wax liquid and the output. The filling time can be controlled by photoelectricity to fill candles of different capacities; the transmission speed and filling time of the mesh belt are controlled by PLC and displayed on the display screen. | ||

| model | XM-GZX1200 length 32m × width 1.2m | |||

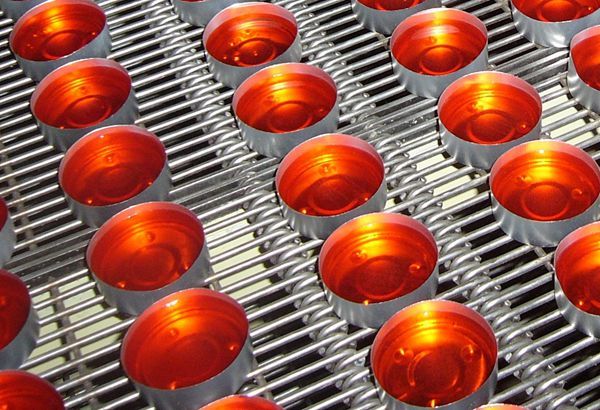

| Varieties of Candles That Can Be Produced | There are container candles. For example, aluminum tea wax, plastic box candles, glass candles, tin candles, ceramic container candles, etc. | |||

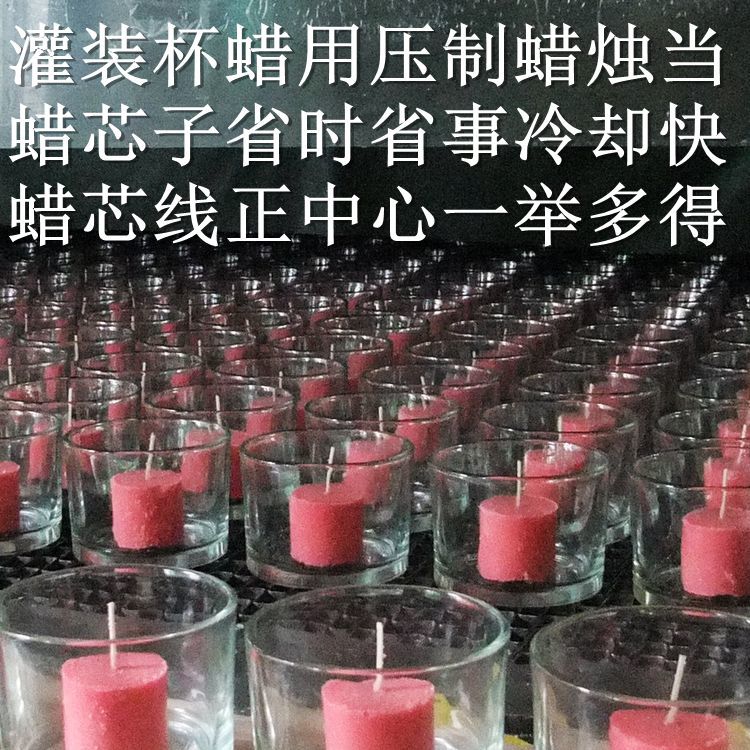

| Candle Finishing Process | Box row→one-time filling of wax liquid→put wax core line→secondary filling of wax liquid→finished candle after cooling | |||

| Wax melting pot temperature range | 0-200 degrees Celsius (computer controlled temperature) | |||

| Waxing pot wax liquid filling capacity | 300 liters | |||

| Candle container diameter range | 0-110mm (other sizes need to be customized) | |||

| Candle container height range | 0-250mm (other sizes need to be customized) | |||

| Hourly output range | 8000 speed adjustable (according to the amount of tea wax) | |||

| Applicable raw materials | Paraffin wax, ghee wax, stearic acid, palm wax, etc. | |||

| Average weight error of finished product | ≤0.2g | |||

| whole line weight | 4000kg | |||

| Machine dimensions | Length, width and height: 32m*1.2m*1.8m | |||

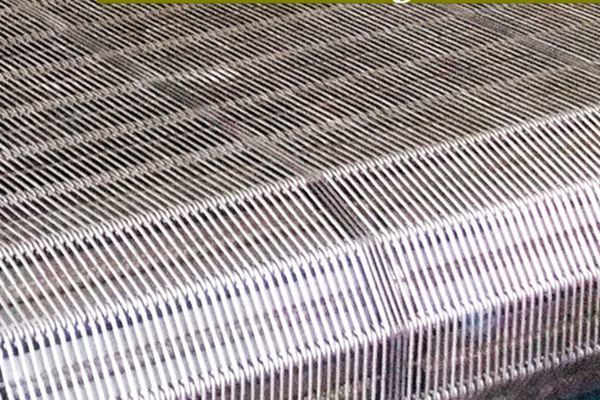

| Power configuration | Total power 20kw; transmission power of mesh belt: 1.5kw voltage 380v | |||

| use: | Suitable for wax liquid filling of various containers. It is flexible and simple to operate, and the intuitive digital display device is more convenient to adjust the filling temperature and time. Widely used in candle companies. It can also be improved and customized according to customer requirements for filling container candles with melted wax liquid as raw materials. Different sizes of filling lines can be customized according to customer requirements. For example, the length of the mesh belt is 40m * 1.3m wide and so on. | |||

| *The above parameters are for reference only, please contact our sales department for exact parameters. | ||||

Sales Contact Manager Zhang: 13704950010

Technical Intelligent Control Contact Manager Huang: 17705081623

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Production of candle varieties: There are container candles. For example, aluminum tea wax, plastic box candles, glass candles, tin candles, ceramic container candles, etc.

Candle completion process: box row, first filling wax liquid and placing wax core wire, second filling wax liquid cooling, finished candle

Wax melting pot temperature range: 0-200 degrees Celsius (computer-controlled temperature)

Wax melting pot wax liquid capacity: 300 liters

Candle container diameter range: 0-110mm (other sizes need to be customized)

Candle container height range: 0-250mm (other sizes need to be customized)

Hourly output range: 8000 speed adjustable (according to the amount of tea wax)

Applicable raw materials: paraffin wax, ghee wax, stearic acid, palm wax, etc.

Average weight error of finished product: ≤0.2g

Whole line weight: 4000kg

Machine dimensions: length, width and height 32m*1.2m*1.8m

Power configuration: total power 20kw; transmission power of mesh belt: 1.5kw voltage 380v

Application: Suitable for wax liquid filling of various containers. It is flexible and simple, and the intuitive digital display device is more convenient to adjust the filling temperature and time. Widely used in candle companies. It can also be improved and customized according to customer requirements for filling container candles with melted wax liquid as raw materials. Different sizes of filling lines can be customized according to customer requirements. For example, the length of the mesh belt is 40m * 1.3m wide and so on.

This product is a special equipment for filling candles. It consists of a container pushing device, a wax liquid filling machine head, a filling box, a conveyor belt, a wax melting box and an ironing box. It is suitable for filling various containers with diameter below 1 10mm and height below 250mm. The machine has two control modes, automatic and manual. The operation is flexible and simple, and the intuitive digital display device is more convenient to adjust the filling temperature and time. The running speed of the conveyor mesh belt is controlled by a frequency converter, and the speed can be adjusted according to the cooling time of the wax liquid and the output. The filling time can be controlled by photoelectricity to fill candles of different capacities; the transmission speed and filling time of the mesh belt are controlled by PLC and displayed on the display screen.

Related Products

Get a free product quote